-

Tel : +86-592-6382791

-

Email : sales@pidmaxwell.com

Tel : +86-592-6382791

Email : sales@pidmaxwell.com

MF43HYC-652A is a 4 channel touch screen temperature controller, works with 4 input and 4 outputs, support thermocouple inputs and output is optional between, SSR Drive, 4-20mA or Realy, PC and cell phone compatible, Modbus TCP/IP optional, 4.3'' touch screen, datalogging feature, with USB, WIFI, and Ethernet port. Operation interface in English, Chinese and Spanish.

Brand:

PIDMaxWellItem no.:

MF43HYC-652AOrdering code:

MF43HYC-652A4.3'' Touch screen 4 channel temperature controller with WIFI and Ethernet port, accessible from PC and cell phone

-Key features

-Maximum 4 channel, you can configure it as 1~4 channel depends on your application

-4.3 inch TFT display, fully touch screen

-Support thermocouple input(K,E,J,N,Wu/Re3-25,S,T,R,B), input field configurable

-Relay/SSR Drive/4-20mA,output optional,specify output when order

-Very easy to configure the controller compare with classic controller

-100~240Vac supply 50/60HZ

-With USB port, Ethernet port and antenna(for WIFI connection)

-Controller can be connected to internet via Ethernet port or WIFI hotspot

-With Cell phone APP(available on both Android and IOS system), User can remotely access and control the controller from cell phone and PC -With basic data logging feature, the controller records process value of each channel.

-Access protection for safety reason

-Parameter restore feature, with just one click, all parameters will be restored to factory default, this is a very helpful features especially when customer is not very familiar with the product

-Run/Stop the controller at any time you want(R/S feature)

-PID control mode or ON/OFF control mode configurable(SET P=0) for ON/OFF control mode

-Auto/manaul control bumpless transfer, output can be configured as 0%~100% under manual control mode

-Fahrenheit Celsius display switch Heating or cooling control mode selectable

-Intuitive interface

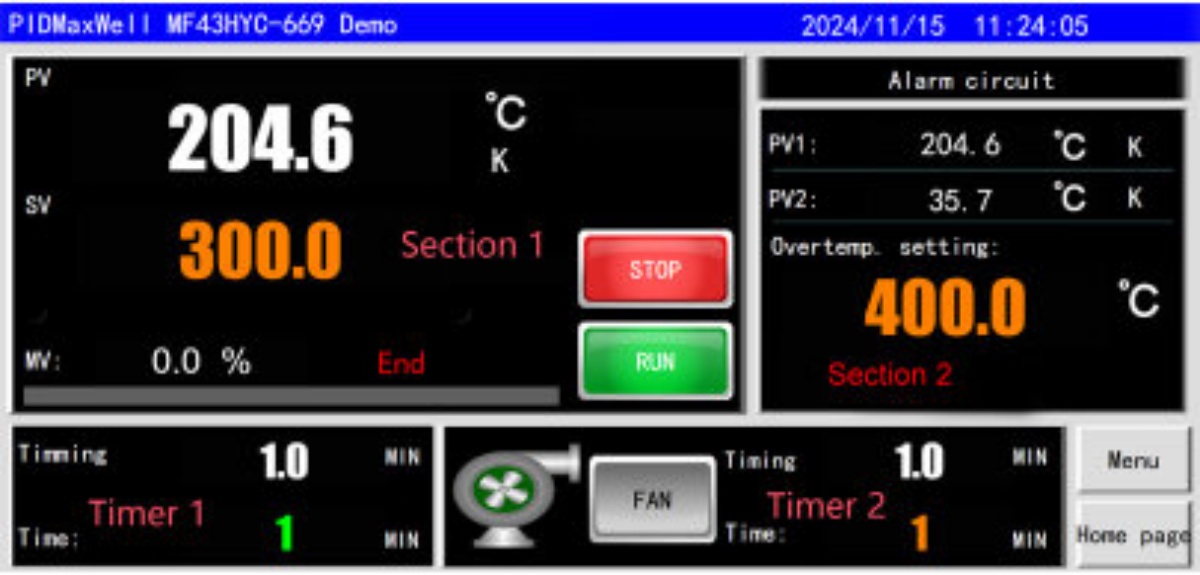

The primary display looks like above image, breakdown the dipslay into 4 sections, section 1, section 2, timer 1 and timer 2

Section 1 is the PID control loop, which displays the process value and setting value and various status indication, like AU1,AU3, AU4, AU5 relay energization.

Section 2 is display for safety Limit Controller purpose with a latching relay output(AU2), and a cross comparison between the reading pick up from sensor 1 and sensor 2, once the undesirable limit reached, the AU2 relay will be triggered and it requires a manual reset.

Timer 1 is the count down timer for the temperature holding time range, when PV reach to SV, the timer will engage automatically and count down process begin

Timer 2 is the count down timer for the circulation fan, for most of oven, there will be significant heat inside the chamber even after the heater stops to work, in this case, it is essential to keep the circulation fan running for certain period of time, the circulation fan kicks-in as long as you hit the RUN button and starts the heating process, but it won't stop at the point when program ends, instead, it will keep running for some time, when heating terminated, the count down timer for circulation fan starts to ticking down and after timer elapsed ,then the fan will be shut down.

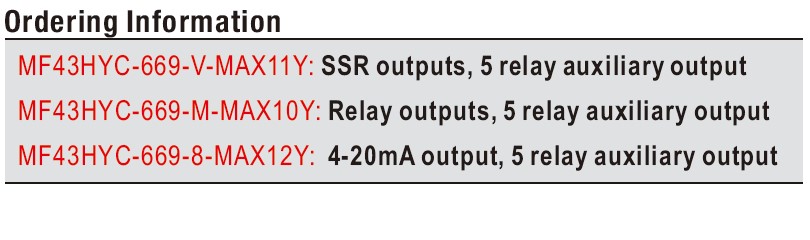

Ordering example:

MF43HYC-669-V-MAX11Y, SSR drive output, 5 Auxiliary output Oven temperature and timer 2 in 1 controller

1)Below videos walk you through on how to create a firing plan with our kiln controller, you can do it on the device or on your cell phone and PC

2)Brief overview of our touch screen wifi kiln oven controller

3)Home screen overview of the kiln temperature controller

Q: What is a ramp and soak controller ?

A "ramp and soak controller" is a device that controls the setpoint of an oven by gradually increasing the setpoint at a predefined rate ("ramping") and then holding it at that value for a specified duration ("soaking"), essentially creating a controlled heating or cooling profile with a gradual transition and a period of constant temperature maintenance; commonly used in applications like ovens and kilns where precise temperature control with controlled heating/cooling cycles is needed.

Key points about ramp and soak controllers:

Function:

They manage the setpoint of a process by changing it over time according to a pre-programmed pattern, including both ramping up/down and holding at a specific temperature for a set duration.

Components:

· Ramp: The phase where the setpoint gradually increases or decreases at a controlled rate.

· Soak: The phase where the setpoint is held constant for a defined period.

· Benefits:

· Preventing thermal shock: By gradually changing temperature, it can reduce the risk of damage from rapid temperature fluctuations.

· Even heating/cooling: Ensures consistent processing throughout a material by providing controlled heating and cooling stages.

· Applications:

· Industrial ovens

· Kilns

· Refractory curing

· · Heat treating processes