4.3'' Touch screen ramp and soak controller

-Key features

Programming a conventional ramp and soak controller with push buttons on the unit can be quite challenge and demanding

This unit is a perfect solution, with easy to use human machine interface integrated. the configuration is very simple and straight forward, this unit is perfect for euipments like hot air dryers, electric Ovens etc

-Saftey feature

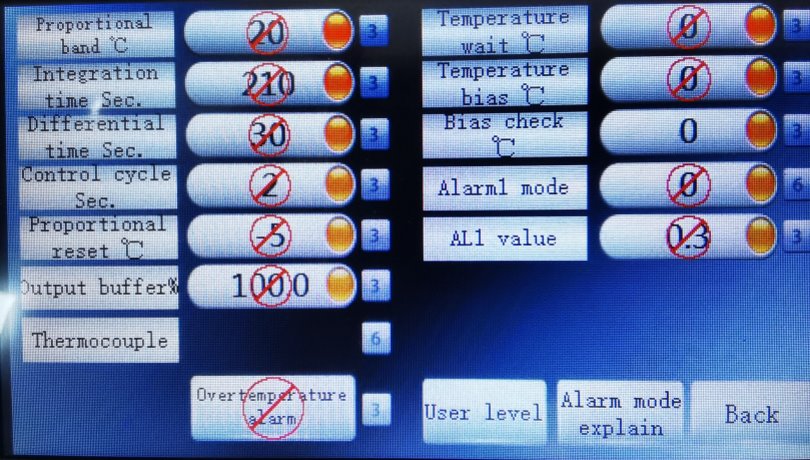

This controller comes with over temperature alarm, Over temperature is a dangerous senario for any given system, an over temperature means the system suffers a serious failure which leads to the over temperature, a satefy mechanism must kick-in when this happens, in a typical control system, a separate high limit controller shall be deployed to detect the over temperature and then generate a signal to shut down the system, there is a built-in high limit alarm in our controller which will engage automatically when over temperature occurs and shut down the system immediately.

- Touch screen ramp and soak controller just like HMI

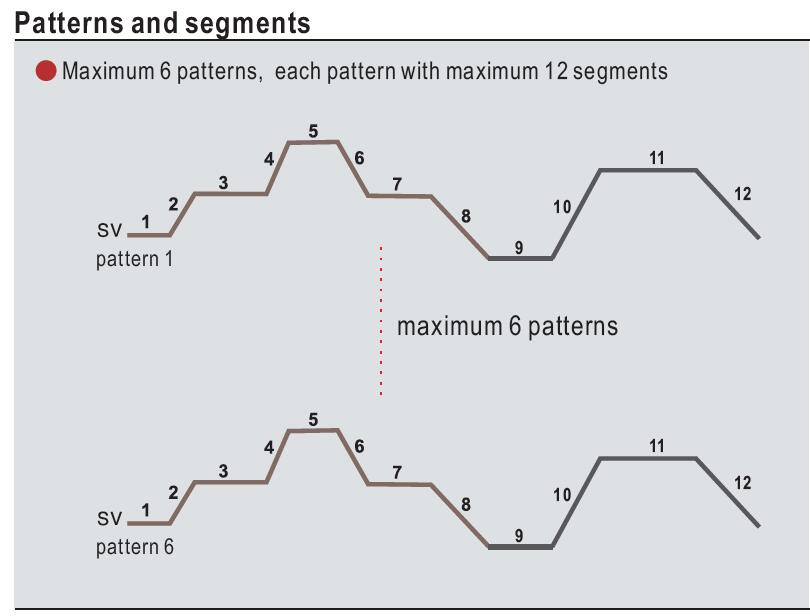

- Maximum 6 patterns, each pattern maximum 12 segments

- 4.3 inch TFT display, HMI+temperature controller 2 in 1

- Support thermocouple input(K,E,J,N,Wre3-25,S,T,R,B), input field configurable

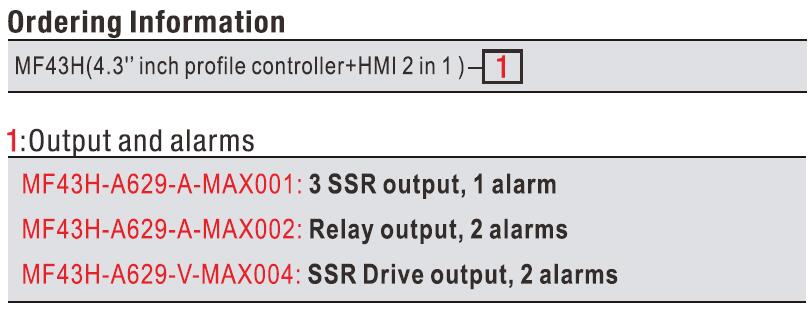

- Relay, SSR Drive, 4-20mA,0-10VDC output optional

- Maximum 2 alarms, multiple alarm modes

- 100~240Vac supply

- Vivid color display, user friendly, very easy to program

- Run, Reset, Jump on the program just one click.

- Output power restriction on each step of each pattern

- With alarm record and real time curve record function

- Very easy to program, only a handful of parameters needs to be set,the setting is easy compare with conventional profiles controllers where end user have to access to multiple parameter levels and configuration can be very annoy

- Quickly switch between each pattern

- Wait function, when program starts, if the PV is less than the starting temperature of the pattern, the program will be put on hold and wait for the PV to reach preset temperature

- Operator access protection

- Clock function, year, date, real time will be displayed on the unit

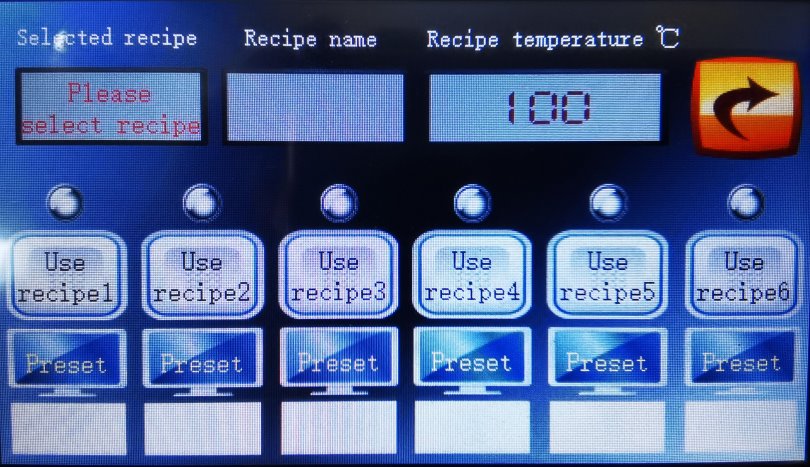

Maximum 6 patterns, each pattern with maximum 12 segements.

Different products being processed in the oven might need different temperature treatment processing. up to 6 patterns can be pre-programmed and stored in the controller and can be selected on the field.

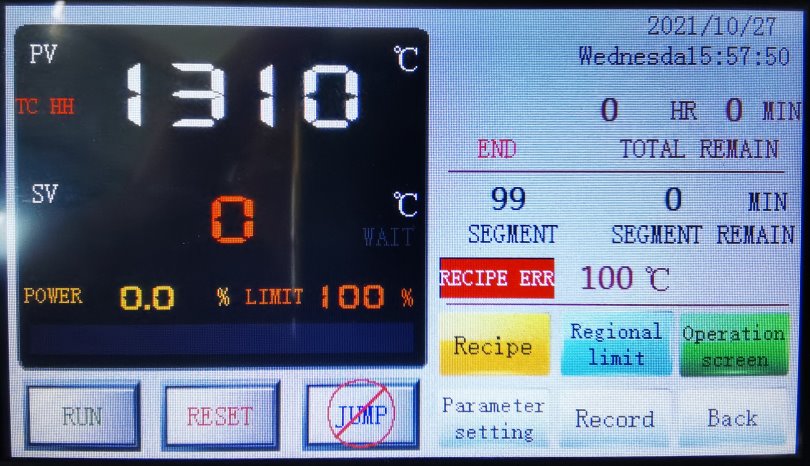

Below is the primary display interface for the unit, you can see the PV/SV, current segment which is under processed,

total segement of the program, and other key information of the profile.

Configuration interface