-

Tel : +86-592-6382791

-

Email : sales@pidmaxwell.com

Tel : +86-592-6382791

Email : sales@pidmaxwell.com

MF43HYC is a touch screen ramp and soak controller, accessible from PC and cell phone, works with both android and IOS system, built-in datalogging features, and data can be downloaded to PC, this item is perfect control solution for Experimental furnace, ceramic kiln, porcelain oven, Pottery oven, jewelry casting oven etc, the conventional ramp and soak controllers or some call it profile controllers on the markets are configured via set buttons on the front panel. end user have to go through layers upon layers of parmaeters and navigate through different parameter during the configuration process. the process could be painful and stressed and often times lead to less efficient and frustration.

Brand:

PIDMaxWellItem no.:

MF43HYC-A629Ordering code:

MF43HYC-A6294.3'' Touch screen ramp and soak controller with WIFI and Ethernet port, accessible from PC and cell phone

-Key features

-Turn key control solutions for ovens in general, namely experimental furnace, ceramic ovens, jewelry casting ovens, porcelain ovens etc.

-6 recipes(or you can call it patterns, or programs depends on which part of the world you are coming from)

-each recipe with maximum 12 segments( we can also do more segments if you want)

-Thermocouple inputs/RTD inputs(RTD inputs needs to be custom made)

-Relay, SSR Drive, 4-20mA output optional

-Remotely access from cell phone and PC, multiple person can have access at the same time,

-Datalogging function, you can download the data to your PC.(PV/SV, alarm information)

-Differnt options on when you want to fire the kiln, you can fire it now or fire it later.

-Easily load the program locally or from PC or cell phone remotely.

-Saftey feature

-Over temperature alarm, one of the key safety features, the entire system can be shut down if over temperature happens. and you can get the message pushed to the APP on your cell phone when over temperature alarm occurs.

-TC break alarm, if you have Thermocouple break during the process, alarm will be triggered and heating will be terminated right away.

Maximum 6 recipes, each recipe with maximum 12 segements.( we can custom made if you need more segments)

Different products being processed in the oven might need different temperature treatment processing. up to 6 recipes can be pre-programmed and stored in the controller and can be selected on the field or selected remotely via PC and cell phone

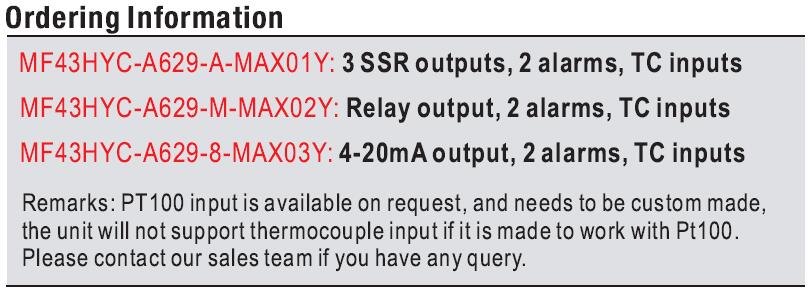

Ordering example:

MF43HYC-A629-A-MAX01Y, SSR drive output, 2 alarms, TC input ramp and soak controller

Click on below link to download documents for MF43HYC

1)Below videos walk you through on how to create a firing plan with our kiln controller, you can do it on the device or on your cell phone and PC

2)Below is a video tutorial on how to connect the controller to internet via WIFI or Ethernet port

3)Below is a video tutorial on how to configure the input and display unit for the controller

4)Below is a video tutorial on how to start the firing process later at some point, for example, scheduled to start the firing tomorrow morning

5)Below is a video tutorial on how to download APP and complete the registration on Andorid device

6)Below is a video tutorial on how to register an account on PC and how to connect the controller to PC

7) Detailed elaboration on the advanced parameters for MF43HYC-A629

8) Elaboration on the "Parameter" from the primary display of MF43HYC-A629

9)Wait function for MF43HYC-A629

10) Detailed explanation on the datalogging feature for MF43HYC-A629

11) Recalibrate the touch screen for MF43HYC-A629

12) Switch between different interface on MF43HYC-A629

13) Explanation on the "system setting" section

14) This video walk you through on how to reboot the temperature controller

15) Detailed explanation on the user management and user login section

Question: MF43HYC-A629 is suitable for oven,kiln who is demanding for precision temperature and time control, some of kiln and oven listed as below:

Experimental furnace

Ceramic kiln controller

Porcelain oven controller

Bakery equipment controller

Pottery oven controller

Jewelry casting oven

Question: What are the essential characteristics for a good kiln controller ?

A good kiln controller is crucial for maintaining precise temperature control and ensuring consistent firing results in ceramic, pottery, or glass kilns. Here are some essential features that a good kiln controller should have:

Temperature Accuracy: The controller should accurately measure and maintain the desired temperature within the kiln. Precision is crucial for achieving the desired firing results.

Temperature Range: It should support a wide range of temperatures suitable for different types of firings, including bisque firing, glaze firing, and specialty firings like raku or crystalline glazes.

Programming Capabilities: A good controller allows for programmable firing schedules, including ramping rates, soaking periods, and cooling cycles. This flexibility enables artists to achieve specific firing profiles for different types of clay bodies and glazes.

User-Friendly Interface: The controller should have an intuitive interface that is easy to navigate and program. This is important for artists of all skill levels to effectively utilize the kiln controller without extensive training.

Safety Features: Safety is paramount when working with kilns. The controller should have built-in safety features such as over-temperature protection, which shuts off the kiln if temperatures exceed safe limits, and error diagnostics to detect and alert users of potential issues.

Compatibility: The controller should be compatible with the type and model of kiln it is intended for. Different kilns may require specific controllers, so compatibility is essential to ensure proper functionality.

Reliability and Durability: A good kiln controller should be reliable and durable, capable of withstanding the high temperatures and frequent use associated with firing ceramics. Quality construction and components contribute to longevity and consistent performance.

Data Logging and Connectivity: Advanced controllers may offer data logging capabilities to track firing cycles and performance over time. Connectivity options such as USB or Wi-Fi allow users to transfer firing data to a computer for analysis or remote monitoring.

Customization Options: Some kiln controllers offer customization options such as user-defined firing programs or the ability to save favorite firing schedules for quick access.

Technical Support and Documentation: Manufacturers should provide comprehensive technical support and documentation to assist users in setting up, programming, and troubleshooting the kiln controller.

Overall, a good kiln controller should provide precise temperature control, flexibility in programming, ease of use, safety features, reliability, and compatibility with the kiln it is intended for. These features contribute to consistent firing results and enhance the overall user experience for ceramic artists.